Feed Screw Rebuilding

How Can One Company $1,500 For Rebuilding a Feed Screw & Another Company Charge $850?

Hard-facing Item #1

Brand X

Some companies are using tig and mig welding to speed up the hard-facing time, but the result is low Rockwell Hardness, and the screws wear out prematurely.

Flite Technology

Flite Technology has invested a considerable amount of money in the latest welding equipment and techniques, providing our customers with a hard-facing with good adherence qualities, fewer voids and cracks which results in a considerably longer screw life.

Straightening Item #2

Brand X

Many companies only straighten their screws with a hammer; YES, we said a hammer. Can you imagine how much stress the base steel and the hard-facing experience in the process, and you wonder why your screw has cracks.

Flite Technology

Flite Technology has a hydraulic press especially designed for straightening feed screws and long shafts. Feed screws are treated gently and are brought back to straightness with no damage to the screw's structural integrity, coating, or hard-facing.

Flight Grinding Item #3

Brand X

A lot of our competitors manually grind the side of the screw flights after hard-facing or tool the excess material off with a lathe. When done manually, they cannot be expected to maintain constant flight widths; and in tooling it off with a lathe, this creates all kinds of havoc with the hard-facing, causing flights to chip, crack, peel off, and who knows what else.

Flite Technology

Flite Technology selects the proper procedure based on the requirements of each hard-facing material used. But the important fact here is that we have flight grinding capacity to properly grind flight sides to maintain proper flight widths, eliminate damage to root diameters and radii that could be caused hard-grinding, and minimize stress to the hard-facing.

Another problem with this industry is that some salespeople low bid a job to get it, and then charge extra for minor repairs. Normally, everything is covered in our quote, unless there is severe damage not previously indicated.

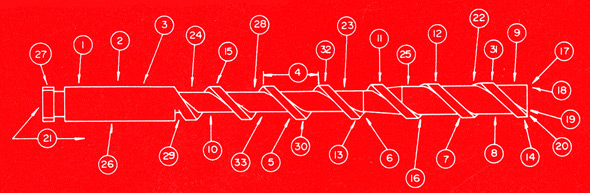

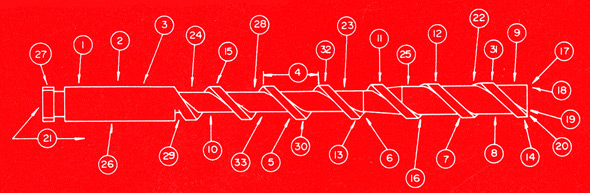

Shown below are some of the defects we have seen on feed screws rebuilt by some of our competitors.

1. Seal area undersized

2. Seal area grooved

3. Seal area out of round

4. Lead distorted

5. Flight angle modified

6. Radii ground erraticall

7. Flight sides full of pits and gauges

8. Root diameter wavy

9. Flight depths increased enormously

10. Screw geometry totally ruined

11. Hard-facing pitted & holey

12. Hard-facing falling off

Hard-facing Item #1

Brand X

Some companies are using tig and mig welding to speed up the hard-facing time, but the result is low Rockwell Hardness, and the screws wear out prematurely.

Flite Technology

Flite Technology has invested a considerable amount of money in the latest welding equipment and techniques, providing our customers with a hard-facing with good adherence qualities, fewer voids and cracks which results in a considerably longer screw life.

Straightening Item #2

Brand X

Many companies only straighten their screws with a hammer; YES, we said a hammer. Can you imagine how much stress the base steel and the hard-facing experience in the process, and you wonder why your screw has cracks.

Flite Technology

Flite Technology has a hydraulic press especially designed for straightening feed screws and long shafts. Feed screws are treated gently and are brought back to straightness with no damage to the screw's structural integrity, coating, or hard-facing.

Flight Grinding Item #3

Brand X

A lot of our competitors manually grind the side of the screw flights after hard-facing or tool the excess material off with a lathe. When done manually, they cannot be expected to maintain constant flight widths; and in tooling it off with a lathe, this creates all kinds of havoc with the hard-facing, causing flights to chip, crack, peel off, and who knows what else.

Flite Technology

Flite Technology selects the proper procedure based on the requirements of each hard-facing material used. But the important fact here is that we have flight grinding capacity to properly grind flight sides to maintain proper flight widths, eliminate damage to root diameters and radii that could be caused hard-grinding, and minimize stress to the hard-facing.

Another problem with this industry is that some salespeople low bid a job to get it, and then charge extra for minor repairs. Normally, everything is covered in our quote, unless there is severe damage not previously indicated.

Shown below are some of the defects we have seen on feed screws rebuilt by some of our competitors.

1. Seal area undersized

2. Seal area grooved

3. Seal area out of round

4. Lead distorted

5. Flight angle modified

6. Radii ground erraticall

7. Flight sides full of pits and gauges

8. Root diameter wavy

9. Flight depths increased enormously

10. Screw geometry totally ruined

11. Hard-facing pitted & holey

12. Hard-facing falling off

13. Hard-facing much too soft

14.Hard-facing chipped

15. Hard-facing has severe cracks

16. Flight edges ground off

17. Register off size & rounded

18. Register out of round

19. Threads buckled up

20. Counter bore angled off

21. Length reduced 3/8"

22. Bent .080"

23. Chrome, wrong type

24. Chrome, too thin

14.Hard-facing chipped

15. Hard-facing has severe cracks

16. Flight edges ground off

17. Register off size & rounded

18. Register out of round

19. Threads buckled up

20. Counter bore angled off

21. Length reduced 3/8"

22. Bent .080"

23. Chrome, wrong type

24. Chrome, too thin

25. Chrome lifting off

26. Seal not Concentric

27. Drive not concentric

28. Root dia not concentric

29. Grind cuts everywhere

30. OD under & over sized

31. OD has chatter marks

32. OD has rough Finish

33. Root dia pitted and holey

26. Seal not Concentric

27. Drive not concentric

28. Root dia not concentric

29. Grind cuts everywhere

30. OD under & over sized

31. OD has chatter marks

32. OD has rough Finish

33. Root dia pitted and holey