| Barrel Honing- Honed to and even oversized dimension and screw flights

rebuilt oversized to acquire original factory clearances and specifications.

Gives barrel another life; screw can later be ground down to match

new barrel. |

|

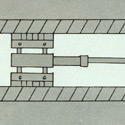

Venting- Flow diverters reduce vent clogging while

minimizing leakage and are also heat conducive. Vent plugs are honed

in position for excellent fit. Stacks added. |

|

Extensions- Barrels extended for longe L/D/ ratios. |

|

Feed Housings Resleeved |

| Cracked- and Broken barrels repaired. |

| Thermocouple- and pressure gauge holes installed or repaired. |

| Output ends- Refaced to correct leakage or pressure drop problems. |

| High Pressure Barrel-End for extra protection and increased structural

intregrity. |

| Jackets- Jacket added to existing barrels to place vents and vent

plugs where none existed before. |

| Rifed Liners

|

| All Stainless Steel Barrels- For extremely corrosive environments.

|

| Super Thick Liners- For applications that can stand considerable wear

on I.D. and must still provide additional protection at this stage

of wear.

|